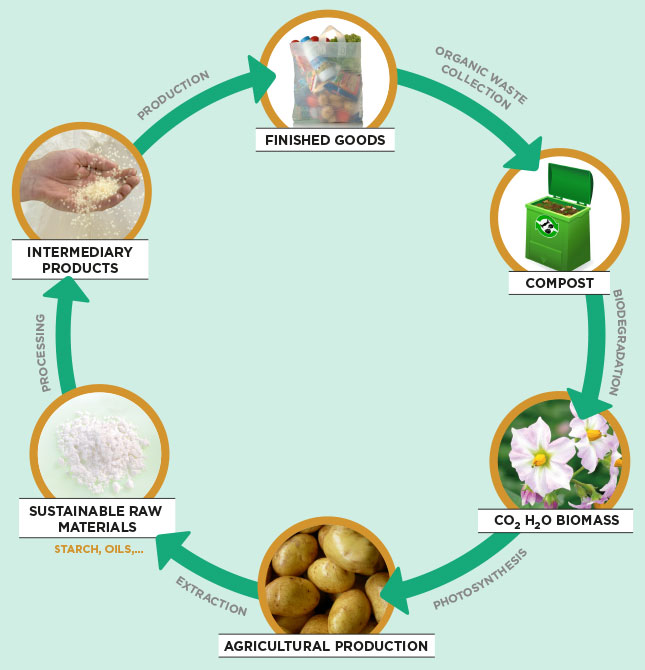

Made from plant-based renewable resources such as potato starch, BIOPLAST resins are a relevant answer to environmental issues. The use of renewable resources by industry effectively saves fossil resources and reduces the amount of CO2 greenhouse gas emissions. Life cycle assesment has shown that biobased plastics lead to a reduction in CO2 of between 30 and 70% compared to conventional plastics, depending on the feedstock, the product and the application.

During its Lead Markets Initiative, the EU Commission determined, that bioplastics are of great interest due, among other things, to their lower carbon footprint.

Biodegradable

According to standard EN 13432, bags or products made from BIOPLAST resins will biodegrade in less than 180 days.

Compostable

In addition to conventional plastics, products made from BIOPLAST have the unique functionality of compostability.This is the preferred end-of-life option for all BIOPLAST resins. They are all perfectly designed to disintegrate in industrial composting units within less than 90 days.

Renewable

According to standard ASTM D6866, BIOPLAST resins contain up to 100% of vegetal resources, mostly potato starch.

Recyclable

Similar to conventional plastics, BIOPLAST resins can be recycled with other plant-based biodegradable bioplastics. It has also been proven that 10% of recycled BIOPLAST in the recycling flux of oil-based PE does not significantly harm the mechanical properties of a comparable blown film made of pure recycled PE.

Incinerable

Composting is, nonetheless, the preferred end-of-life option but if collected with general waste, products made from BIOPLAST resins can also be incinerated and generate attractive calorific value.

Plasticizer-free

All BIOPLAST resins, except BIOPLAST TPS®, are plasticizer-free, thus responding to consumer requirements while also assuring excellent processability.